Horizontal Boring Machine Line Diagram

As regards its importance it is second only to the lathe machines holes were drilled by the egyptians in 1200 b c.

Horizontal boring machine line diagram. One of the major uses is when parts are larger in size and crane is to be placed overhead. Head stock vertical travel y axis 1120 mm. Porta mole also cleans culvert drains and core bores curbs and foundations. Porta mole underground boring machines are used to put pipe cable or conduit under paved surfaces.

A horizontal boring machine can perform boring reaming turning threading facing milling grooving recessing and many other operations with suitable tools. The drilling machine is defined as a machine which is used to make a circular hole a tool used to drill the holes of different size and other related operations using a drill bit. Cnc big bore lathes flat bed this large capacity cnc lathe with 2 axes servo drive offer simply many complicated turning operations. An important early lathe in the uk was the horizontal boring machine that was installed by jan verbruggen in 1772 in the royal arsenal in woolwich.

The drilling machine is one of the most important machines in a workshop. Horizontal boring machine remains static and the boring tool is rotated. Used by landscape contractors cable installers electrical contractors. Vertical boring machine vbm 1.

About 3000 years ago by. Horizontal boring machine parts. Typically there are 3 linear axes in which the tool head and part move. Directional boring hdd offers significant environmental advantages over traditional cut and cover.

Boring spindle diameter 100 mm. Working of horizontal boring machine. Table type horizontal boring machine hbm 5. Uses horizontal boring machine is used in boring shaping facing milling and drilling.

Cnc horizontal boring machine specification. Porta mole will bore 2 to 13 5 to 33cm in diameter and up to 200 60m in length in sand clay and hard rock soil conditions. It is ideal for most industrial applications including job shops oil field power utilities and ship building. A horizontal boring machine has its work spindle parallel to the ground and work table.

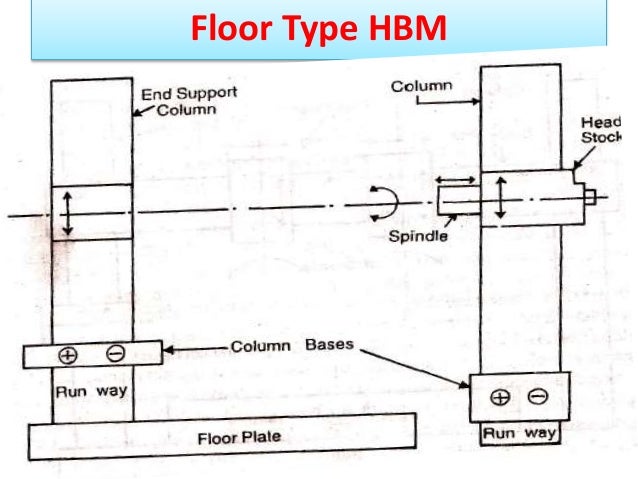

Single column vbm 2. It was horse powered and allowed for the production of much more accurate and stronger cannon used with success in the american revolutionary war in the late 18th century. Components of a boring machine bed floor plate base table column head stock end supporting column cross rail. Double column vbm c precision boring machine d jig boring machine 4.

Convention dictates that the main axis that drives the part towards the work spindle is the z axis with a cross traversing x axis and a vertically traversing y axis. In a horizontal boring machine the work is supporting on a table which is constant and the tool turns into a horizontal axis. Multiple spindle hbm b.