Grinder Pump System Maintenance

Save thousands of dollars by learning best practices and useful tips on grinder pump installation.

Grinder pump system maintenance. In the case of a grinder pump a sump pump connected to the sewer system may raise your electric rates and shorten the life of your grinder pump. Need grinder pump installation or maintenance. This process will clean the pump and leave it filled with a minimum of clean water. Features omnivore grinder pump with new v slice cutter technology.

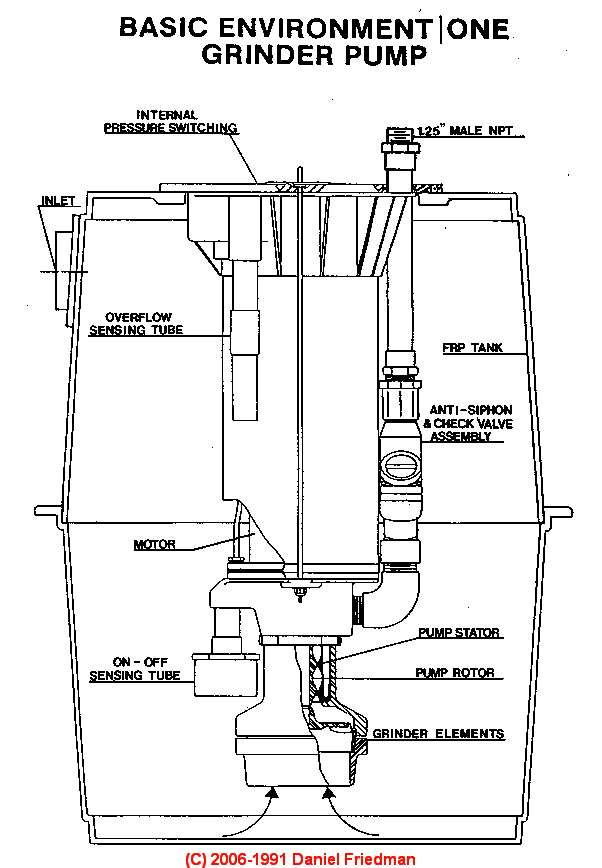

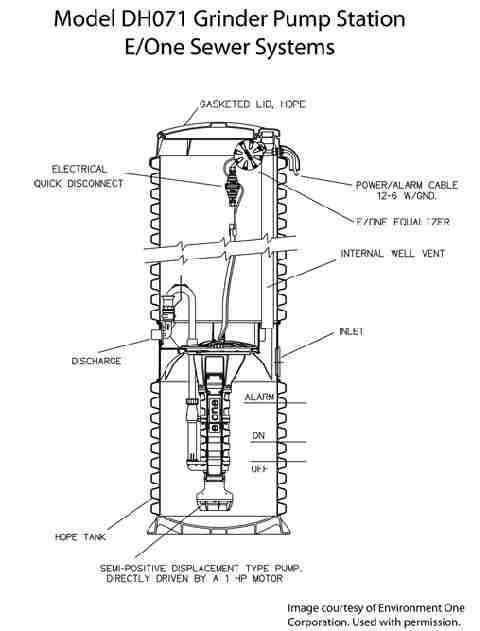

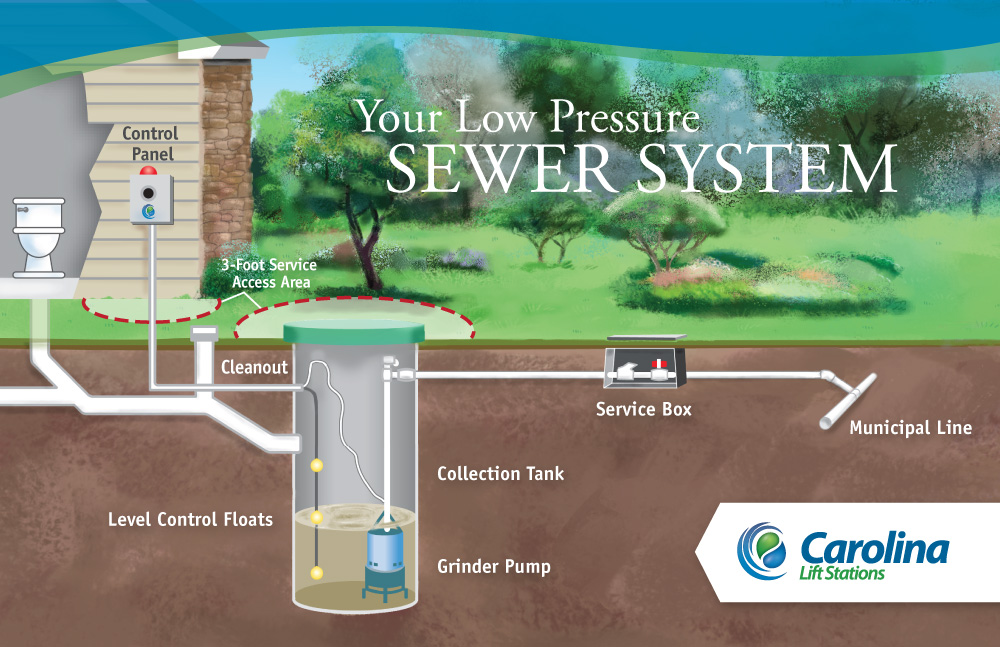

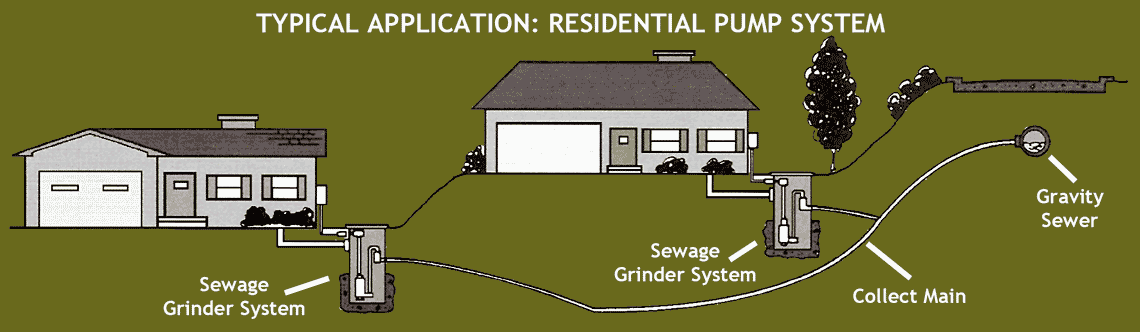

Rising wastewater should lift the float that in turn operates a switch that turns on the pump. A pressure sewer system uses small diameter pipes and grinder pumps installed at each home. At septic pump alarm systems. Unassembled grinder system with alarm includes 24 and 30 diameter fiberglass basin with anti float collar 2 hp omnivore grinder pump with 1 1 4 discharge.

The dpw currently maintains 159 publically owned grinder pumps. Step 3 conduct yearly maintenance. The grinder pump station collects all of the wastewater from the home and grinds it into slurry. Inspect pump motor and bearings.

Inspect oil level and check for contamination in septic grinder pump motor chamber. Inspect grinder pump motor seal for wear and possible leaks. The homeowner shall be responsible to maintain the ground around the pump basin within a 5 foot radius so that the ground is sloped enough to prevent rainfall from pooling next to the basin and entering the lid or vent. The pump will run until the tank is empty and will shut off.

If you do not know if your grinder pump system is publically or privately owned contact the dpw at 860 448 4083. It will also cut back on odors caused by materials that are in the grinder between flushes. Homeowners can find answers to all of your grinder pump related questions here. Always leave the electrical power on.

Grinder pumps should not require preventive maintenance. However grinder pumps that use floats to sense the level in the holding tank are prone to grease buildup that may turn the pump on unnecessarily or not turn on the pump at all causing the tank to fill up and sewage to possibly back up into the home or yard. If your sewage grinder pump or sump pump is not turning on and off correctly check the holding tank for clogging debris and check the operation of the sewage pump float control switch. After the pump turns on turn the water off.

During your septic grinder pump maintenance routine you should do the following. Northern arizona s premier grinder pump specialists. It is usually a good idea to go ahead and have a plumber come by once a year to do some maintenance on your system. The wastewater is then pumped to a larger sewer main or directly to a wastewater treatment plant.

If you simply flush lemon juice down your toilet it will help to break up any clogs and keep your grinder pump clean and running properly. Inspect pump impeller and body for any clogs or clotting buildup.