Glaze Coat Epoxy Problems

Sticky or soft spots.

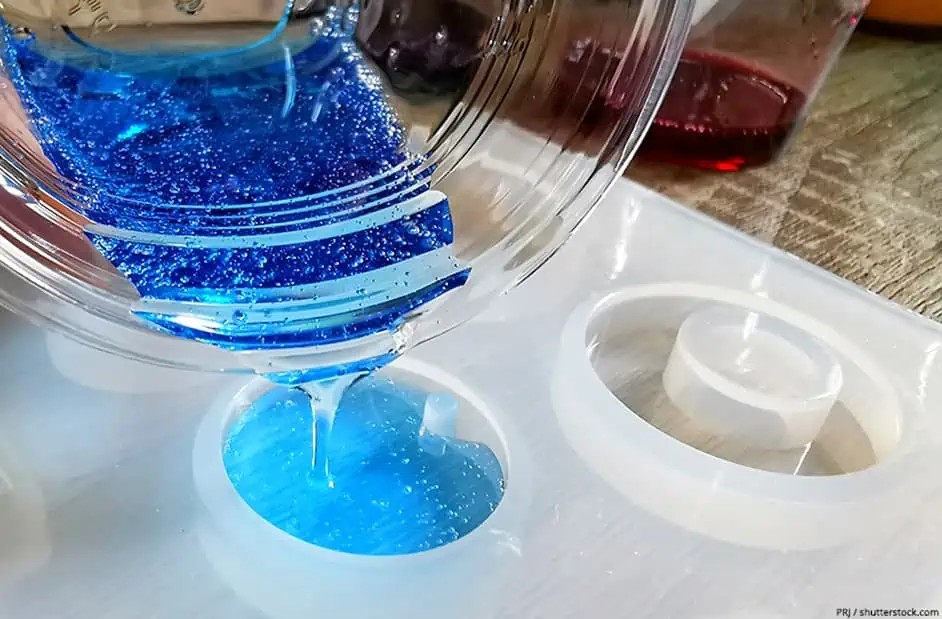

Glaze coat epoxy problems. This is referred to as a glazed coat epoxy problem. Sticky or soft spots are the result of improper mixing. The most common problems with epoxy and how to avoid them. This easy to use 1 1 ratio is ideal for household and craft projects just one pour.

Famowood glaze coat high build epoxy coating is an ultra clear high gloss finish epoxy versatile enough to be used on just about any surface either smooth or rough stained or painted. If your epoxy has already cured and you have fish eyes you will need to pour another coat over the epoxy. Glaze coat application on bar top. Glaze coat epoxy problems.

After epoxy is poured and has cured for 36 hours the surface should be hard and smooth. So the handyman suggested famowood brand glaze coat high gloss finish. Colder than recommended epoxy can also be used with a special hardener which lets the epoxy cure at lower temperatures. Read honest and unbiased product reviews from our users.

Your epoxy coat could become cloudy. Glaze coat famowood wood filler seal all adhesive quickhold adhesive e6000 adhesive e6100 non sag adhesive e6800 uv resistant self leveling glue all purpose adhesive mend vacuum cleaner attachments seal worn or cracked water hoses repair broken ceramic flowerpots marine epoxy paste goop super mend automotive epoxy paste. He built up a 1 16 dam around the edge of the desk mixed it up and poured it in. To prevent problems with cup method of mixing.

Reason 1 humid conditions and moisture. Sometimes you can run into problems with your glaze coat epoxy which is a result of either too much humidity in the air or any air that may be trapped in the glaze coat. It ran over the sides a bit as it leveled out. This could be the result of humid conditions or moisture from condensation which reacted with the components of your mixture before the epoxy could cure.

This easy to use 1 1 ratio is ideal for household and craft.