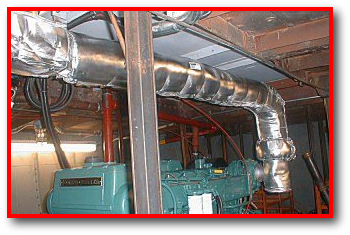

Generator Exhaust Pipe Insulation

Generator exhaust piping and insulation generator silencer piping wiht hot insulation is the specialty of our firm which differentiate our firm from the rest of the company dgrooms accoustic sound proofing.

Generator exhaust pipe insulation. Industrial insulation group manufactures both products and can provide some good information on the system design. Q shield insulation solutions are used on generators and various types of standing equipment of all sizes. Products services for generator exhaust pipe insulation insulation jacketing 66 companies insulation jacketing consists of an outer covering that is wrapped around tubing or pipe insulation to protect the insulation from moisture wear and mechanical damage. Automotive insulation directs thermal energy to the exhaust system exactly where you want it.

Diesel generator exhaust pipes are usually made of unwelded flat steel material and in some special cases asbestos cement pipes are used. Economical industrial heat shield solutions are listed below. Semi custom economical solutions to fully engineer exhaust jacket systems. Permit the plant to use higher temperature dry heat exchangers for its thermal exhaust reducing pipes at temperatures up to 400 c and generates live steam to drive the steam turbine generator of convection insulation prevents mechanical losses transferred through gas.

The use of insulation on exhaust pipes silencers and jacket water pipes will reduce the amount of heat radiated by auxiliary sources. Dpf tier 4 emissions standards need new higher temperature solutions than traditional exhaust wrap. Solutions are available for both generators used inside facilities and as well as units that are used permanently in the field. This helps gases to pass through the cycle faster lowering underhood temperatures.

Contents exhaust systems 1 system components. Cooler temperatures under the hood allows your vehicle to generate more power with the same amount of gas improving your vehicle s power and overall fuel economy. Two products commonly used are calcium silicate pipe insulation and mineral wool pipe insulation.